Wednesday, January 15, 2014

All Of Your Refrigerant Needs Under One Roof

Monday, September 16, 2013

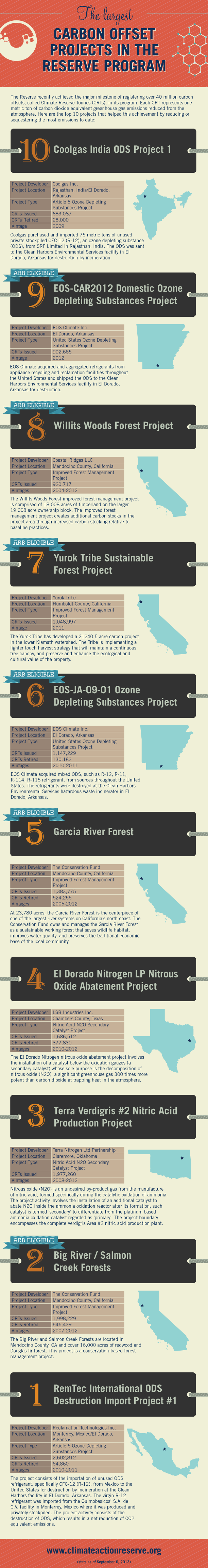

Top ten projects that have earned the most CRTs in the Reserve

Safeway Must Fix Ozone-Depleting Refrigerant Leaks Nationwide

Tuesday, August 27, 2013

End Of The Season Reduction Sale

A-GAS RemTec is an EPA certified reclamation facility

Monday, August 26, 2013

Stopped Cold: Mercedes Sales Blocked in France

The French environment ministry ordered the ban in response to the German carmaker’s defiance of a European Union regulation on the refrigerants permitted in automotive air-conditioning systems, and the ministry says that it won’t back down until Daimler, the parent of Mercedes, complies. The European Union, though supportive of France’s position, has agreed to step in and referee to keep the squabble from spreading.

Tuesday, August 20, 2013

A-Gas RemTec's Refrigerant Consignment Program

Tuesday, January 29, 2013

DuPont Wins Counterfeit Case

In 2009, a distributor alerted DuPont to potential counterfeiting of DuPont Suva and DuPont Freon brands. The information they provided led Dupont to suspect counterfeiting activity of Quzhouzhou Fuming Co. Ltd., in Quzhou City. With assistance from a local law firm, DuPont requested that local authorities conduct a raid of the suspected counterfeit facility. A raid action in late September 2011 resulted in the seizure of 1,500 empty refrigerant cylinders with DuPont Suva and Freon packaging, 1,000 counterfeit labels, and 1,000 counterfeit DuPont Freon R-22 cylinders.

After the raid, DuPont issued cease-and-desist letters, however, the company did not respond to the request and continued to sell the counterfeit refrigerants. In response, DuPont filed legal action against those responsible.

A court case was undertaken in China and a judicial settlement was reached in August 2012. The defendant was required to pay the equivalent of $39,400 to the Chinese government and $32,000 in damages and court costs to DuPont. The company is under a permanent injunction to not sell DuPont refrigerants or engage in counterfeit activities involving DuPont trademarks going forward. As part of the sentence, the judge also required the company to post a formal public apology in two Chinese newspapers.

“We will continue to combat counterfeiting of DuPont refrigerants, using assistance from local law enforcement, government officials, and customs organizations,” said Greg Rubin, DuPont global business manager. “This effort is ongoing and this case was an excellent example of cross-regional work between DuPont and our distributors. This is a collaborative effort. We can’t combat counterfeiting alone.”

Publication date: 1/21/2013 AHRI THE NEWS

Friday, January 14, 2011

Recover, Recycle & Reclaim

The following describes the specific differences between refrigerant recovery, recycling and reclamation:

The following describes the specific differences between refrigerant recovery, recycling and reclamation:Recover

To remove refrigerant in any condition from an appliance and store it in an external container without necessarily testing or processing it in any way.

Refrigerant RECOVERY involves the removal of a refrigerant from a system and the placement of that refrigerant into a container. The recovery process:

Is conducted whenever technicians need to open or dispose of air conditioning or refrigeration equipment.

Includes removal of refrigerant vapor (heels) to established vacuum levels to maximize the amount of refrigerant captured and minimize releases. Examples of recovery/recycling machine design safety are included in Underwriters Laboratories (UL) 1963, and performance specifications are included in Air Conditioning and Refrigeration Institute (AHRI) 740.

Involves service technicians, equipment operators, appliance disposal facilities, equipment and refrigerant manufacturers.

Recycle

To extract refrigerant from an appliance and clean refrigerant for reuse without meeting all of the requirements for reclamation. In general, recycled refrigerant is refrigerant that is cleaned using oil separation and single or multiple passes through devices, such as replaceable core filter-driers, which reduce moisture, acidity, and particulate matter. Under section 609, refrigerant can be removed from one car's air conditioner, recycled on site, and then charged into a different car.

Refrigerant RECYCLING involves processing used refrigerants to reduce contaminants, then reusing the refrigerant.

- Recycling is recommended only when recharging to the same owner's equipment.

- Recycling involves removal of some contaminants prior to reuse. Contaminants can result in early system failure. Contaminants include oil, moisture, acid, chlorides, particulates, and non-condensable gases.

- The Industry Recycling Guide (IRG-2) published by ARI describes maximum recommended levels of impurities.

- International Organization for Standards (ISO) 11650, Society of Automotive Engineers (SAE) J1990 or AHRI 740 standards may be used to measure recovery/recycling equipment performance.

Reclaim

To reprocess refrigerant to at least the purity specified in the ARI Standard 700-1993, Specifications for Fluorocarbon Refrigerants, and to verify this purity using the analytical methodology prescribed in the Standard. Reclamation requires specialized machinery not available at a particular job site or auto repair shop. The technician will recover the refrigerant and then send it either to a EPA certified reclaimer, http://www.epa.gov/ozone/title6/608/reclamation/reclist.html, or back to the refrigerant manufacturer.

Refrigerant RECLAMATION involves purifying used refrigerant to meet industry product specifications.

- Reclamation identifies bad or mixed refrigerants which could result in equipment damage or leakage. Chemical analysis also is required to verify specification values to meet or exceed product standards. (e.g. ISO 12810, AHRI 700).

- Reclamation may include filtering, separation, distillation, dilution, or reformulation of the recovered refrigerant.

- Reclamation is recommended when used refrigerants will be charged into equipment other than the equipment it was removed from, or into equipment owned by a different company.

- The U.S. Environmental Protection Agency (EPA) requires that reclaimed refrigerant must attain AHRI 700 or ISO 12810, or equivalent specification prior to resale.

- Reclamation facilities and processes should be designed to minimize emissions.

- Non-reclaimable refrigerants should be disposed of in an environmentally acceptable manner, and in accordance with applicable regulations.